In recent years, DIY culture has exploded, with more and more people embracing the hands-on approach to crafting, building, and creating. From home décor to functional tools, the possibilities seem endless. One of the most exciting technologies driving this revolution is laser cutting. With its precision, versatility, and accessibility, laser cutting is transforming the way makers approach their projects. Whether you’re a seasoned DIYer or just starting, laser cutting can take your creations to the next level.

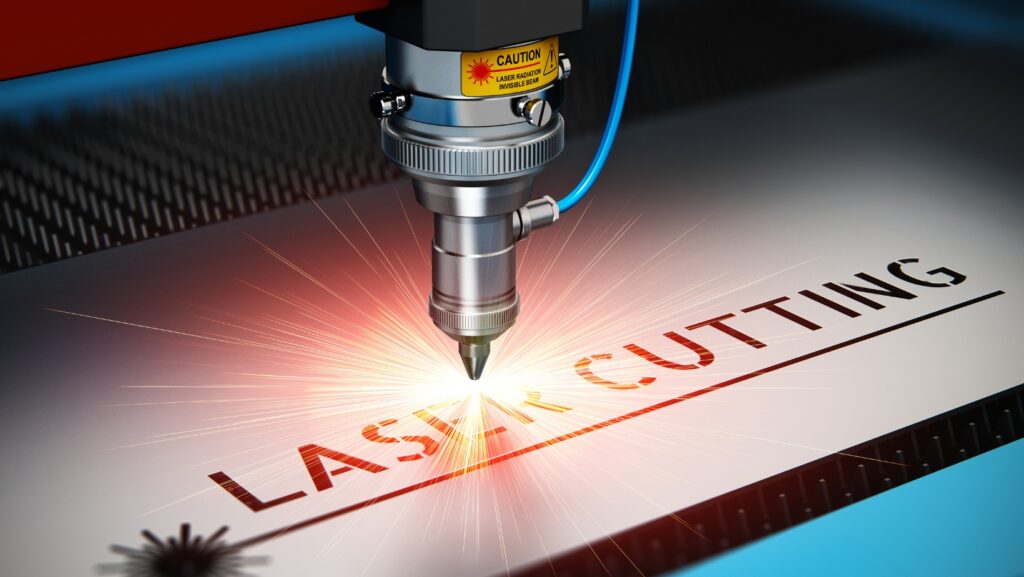

What is Laser Cutting?

At its core, laser cutting uses a high-powered laser beam to cut or engrave materials like wood, acrylic, metal, and even fabric. The laser works by focusing intense heat on a specific point, which melts, burns, or vaporizes the material, allowing for incredibly precise cuts and designs. While laser cutting was once the domain of industrial applications, today, it is more accessible than ever to hobbyists and DIY makers.

Popular materials for laser cutting include plywood, MDF, acrylic, leather, and even certain metals. Each material responds differently to the laser, but the ability to create clean, accurate cuts with little to no waste makes it ideal for DIY projects.

The Benefits of Laser Cutting for DIY Makers

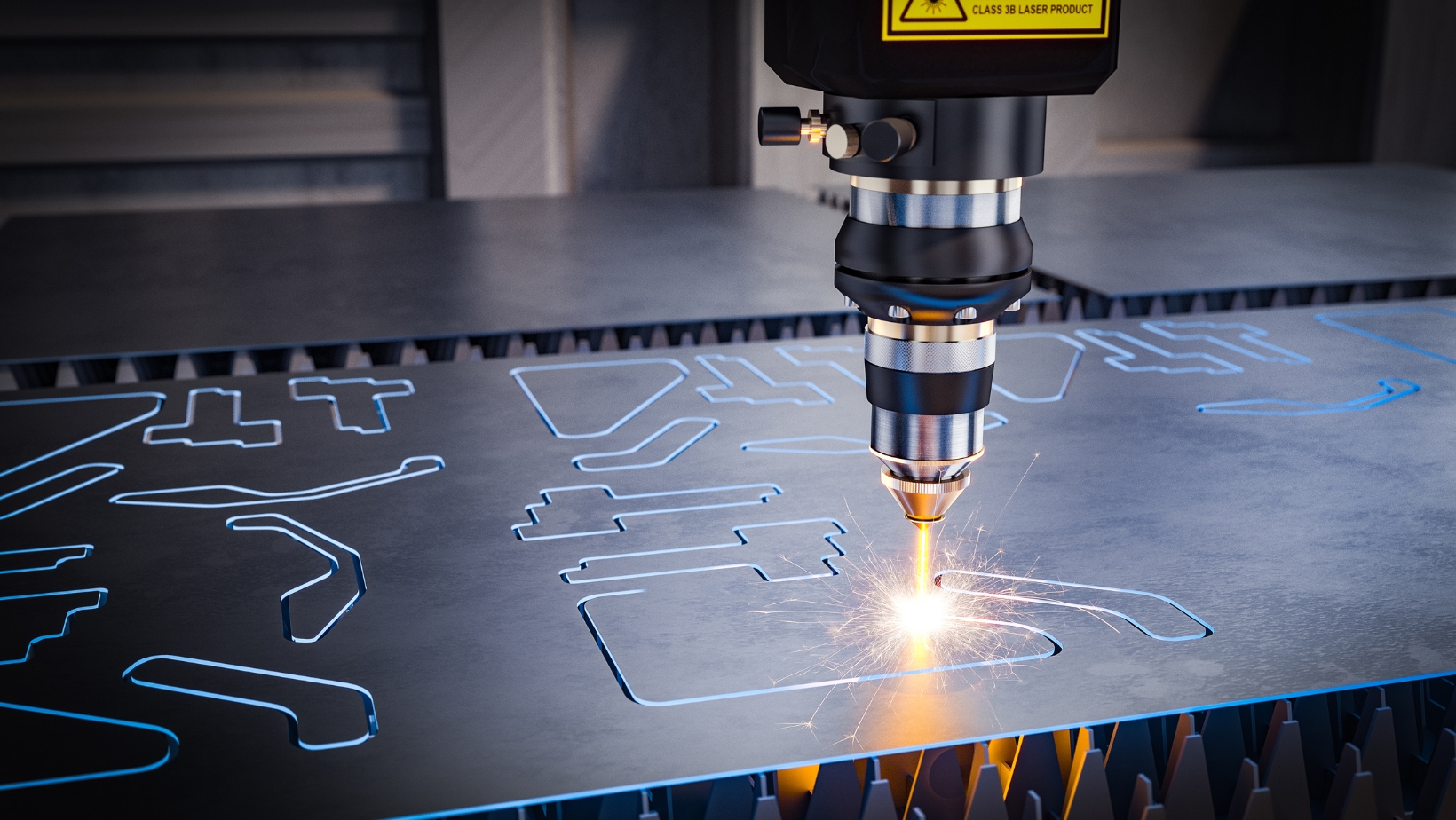

Laser cutting offers several benefits that make it an ideal tool for makers. First and foremost, it allows for precision and detail that are hard to achieve with traditional cutting methods. Whether you’re crafting intricate designs for home décor, personalized gifts, or custom tools, a laser cutter can execute designs with incredible accuracy—often down to the millimeter.

Speed and efficiency are also key advantages. Laser cutting drastically reduces the time it takes to bring an idea to life. For example, a project that might take hours to cut by hand can be completed in a fraction of the time with a laser cutter. This efficiency is especially valuable for small batch production or one-off custom items, where speed is crucial.

Moreover, laser cutters are incredibly versatile. It can be used to create both functional and decorative items, from everyday tools to stunning artwork. The technology also allows for a high degree of customization, which is perfect for personalized gifts or custom business products.

How Laser Cutting is Used in Popular DIY Projects

For DIYers, laser cutting opens up a world of creative possibilities. In the realm of home décor, it has become a go-to method for creating custom wall art, intricate lampshades, and even furniture pieces. The precision of laser cutting allows for detailed patterns and designs that would be difficult or time-consuming to achieve with other tools.

When it comes to personalized gifts, laser cutting and engraving are game changers. DIYers can create custom items such as engraved wooden boxes, personalized keychains, or etched glassware. The level of detail that can be achieved with laser engraving makes it easy to add a personal touch to any gift, whether for a birthday, wedding, or special occasion.

Laser cutting is also a powerful tool for crafting functional items. Makers use it to create custom stencils, tool organizers, and even replacement parts for other projects. The ability to create precise, tailor-made tools and components gives DIYers the freedom to build projects that suit their specific needs without the limitations of off-the-shelf solutions.

For small business owners, laser cutting provides a unique opportunity to create custom products in small runs. From bespoke jewelry to branded merchandise, laser cutting allows entrepreneurs to offer one-of-a-kind items that stand out in a crowded market.

Breaking Down Barriers: Accessibility and Affordability

In the past, laser cutting was limited to large industrial operations, but the cost of laser cutters has dropped significantly in recent years, making them more accessible to hobbyists and small-scale makers. Entry-level laser cutters can now be found at relatively affordable prices, allowing DIYers to bring this advanced technology into their own workshops.

Online platforms and maker communities have played a significant role in making laser cutting more accessible. Websites like Instructables, Etsy, and various online forums provide resources, tutorials, and design files, making it easier than ever for DIYers to get started with laser cutting. Additionally, local maker spaces and community workshops often offer access to laser cutters, allowing people to try out the technology without investing in expensive equipment.

Moreover, user-friendly software has made laser cutting design more intuitive. Programs like Adobe Illustrator, CorelDRAW, and XCS for xTool laser cutters, as well as free alternatives like Inkscape, enable makers to create intricate designs with ease. Many laser cutters come with their own software, which simplifies the process further, allowing users to go from concept to cut in no time.

Overcoming Common Challenges for DIY Makers

Despite its many advantages, laser cutting does come with its own set of challenges. One common issue is selecting the right materials. Not all materials are suitable for laser cutting, and some may emit harmful fumes when cut, requiring proper ventilation. Additionally, different materials may require different laser settings, such as power, speed, and focus, which can take some time to master.

Another challenge is machine setup and maintenance. Although modern laser cutters are relatively easy to operate, they still require regular maintenance and occasional troubleshooting. Learning how to calibrate the machine and perform routine upkeep is an important part of the process, especially for those new to the technology.

Lastly, there’s the learning curve of designing for laser cutting. While laser cutters are incredibly precise, creating a design that translates well into a finished product can take some practice. Beginners may initially struggle with software or understanding the nuances of creating designs that work perfectly with the machine. However, with practice and access to online resources, these challenges can be overcome.

The Future of Laser Cutting in the DIY Community

As technology continues to advance, the future of laser cutting in the DIY community looks promising. New innovations in laser efficiency, material compatibility, and automation will likely continue to improve the accessibility and capabilities of laser cutters. For instance, lasers with greater precision and power will open up possibilities for cutting more materials and achieving even finer detail.

Additionally, the integration of laser cutting with other technologies like 3D printing and CNC machines is expanding the potential for makers. These tools, when used together, offer nearly limitless creative opportunities for DIYers, allowing them to combine cutting, engraving, and shaping techniques into one cohesive project.

Maker spaces and community workshops will also continue to grow, making laser cutting accessible to an even larger audience. As more people gain access to this technology, the maker movement will thrive, and the possibilities for DIY projects will only expand.

Conclusion

Laser cutting has undoubtedly revolutionized the DIY world, offering makers the ability to create precise, intricate, and custom pieces with ease. With its growing accessibility, versatility, and potential for innovation, it’s no wonder that laser cutting has become a staple tool for makers everywhere. Whether you’re crafting home décor, personalized gifts, or functional tools, laser cutting opens up new realms of creativity and efficiency. If you haven’t yet explored this incredible technology, now is the perfect time to dive in and see how it can take your DIY projects to the next level.